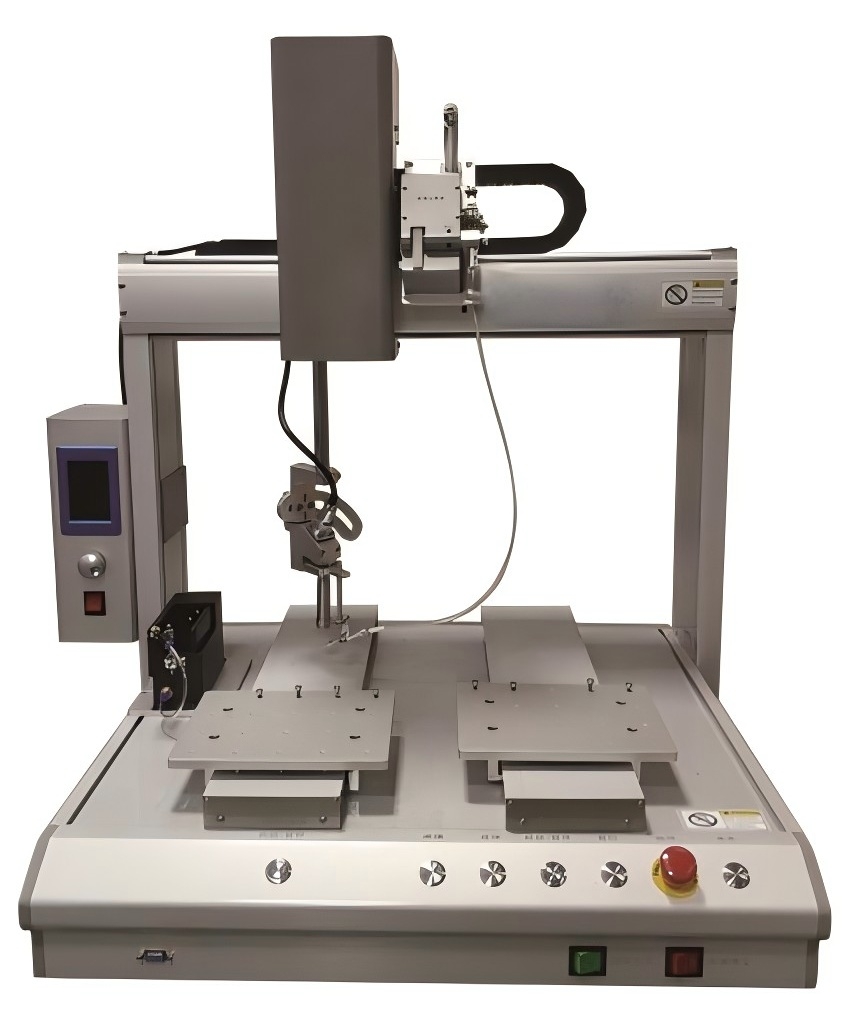

with single head and two working platforms

Features:

- Flexible and diverse soldering methods, with spot and drag welding (pull welding) etc. functions.

- Aluminum profile open casting, no deformation, no rust, stable operation.

- Programming supports point-to-point, block-to-block replication arrays to reduce program time.

- Each movement shaft adopts Lesai closed-loop motor to improve equipment reliability and life.

- Equipped with automatic cleaning function, improve product quality and soldering tip life.

- The welding module has a buffer function to effectively reduce the damage of the product.

- Temperature range 150-480℃, display real-time power consumption, PID algorithm and frequency conversion technology.

- With tin breaking function, effectively reduce the splash of tin slag, improve the product quality.

- Support the configuration of smoke purifier to solve the problem of solder smoke.

| Models | KLD-5331R | |

| Stroke of each axis | X | 500mm |

| Y1 | 300mm | |

| Y2 | 300mm | |

| Z | 100mm | |

| R | 360°±2° | |

| Payload | Working load | 5KG |

| Tool load | 3KG | |

| Motor | Type/Power | 57 Closed-loop motor (400W servo motor as option) |

| Driver | Closed-loop driver (400W servo driver as option) | |

| Driving mode | Synchronous belt + guide rail (Lead screw+guide rail as option) | |

| Power supply | AC220V,50Hz | |

| Rated power | Max 350W | |

| Driving power | Voltage | 24V DC |

| Current | Max 3.5A/Axis | |

| Temperature control type | 50-500 ℃(400W)(200W/150W/600W etc. as option) | |

| Heating core | 400W(200W/150W/600W etc. as option) | |

| Silk supply method | 0.5-1.2mm (with detinning, other wire diameter can be customized) | |

| Dimension | L820*W600*H820(mm) | |

| Weight | 65KG | |