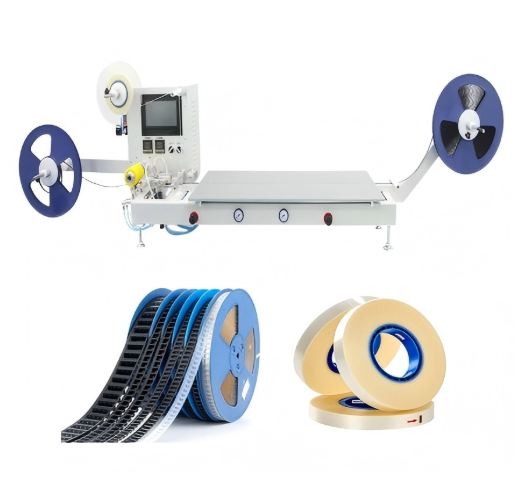

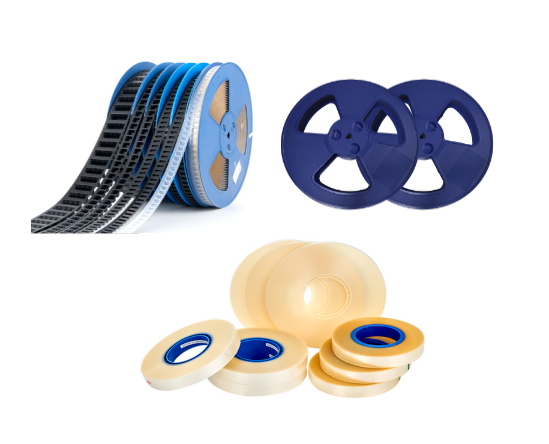

(Can be customized with different molds for different carrier tape)

- Introduction:Suitable for the packaging materials of SMD components in batches, and can be easily and quickly replaced with different widths and different specifications.Suitable for all types from 12mm to 104mm.The plastic carrier belt has perfect performance for PS, PC and A-PET thick material molding. Adopt Japan “Mitsubishi” PLC control machine operation, Weinview LCD touch screen as the man-machine interface. PLC automatic control of winding tape, tape out, counting, and other functions. Support manually adjust the heating, forming, punching, pulling, cutting and other parameters, and has a lack of material alarm function, high reliability, flexible and convenient. Weinview LCD touch screen can display all the status parameters, and can be set all the status parameters, the display function is powerful. Centralized control, easy operation, friendly interface and flexible upgrade are the features of this machine.

| Model | KLD-900CTF |

| Forming speed | Around 150-360m/h(Depending on product complexity) |

| Carrier tape size | 12-88(mm) |

| Tape release disc diameter | ≤560mm |

| Carrier tape thickness | ≤0.6mm |

| Carrier tape height | ≤25mm |

| Receive tape disc diameter | ≤500mm |

| Heating temparature | Normal temperature~260℃ continuously adjustable |

| Power supply | AC220V, 50Hz, Power: 2.5KW |

| Air source | 8.0kg/cm 20.7±0.1kg/cm 2 |

| Ambient temperature | -5℃~40℃ |

| Ambient humidity | 0% ~ 92% RH(non-condensing) |

| Dimension | L3000*W600*1660(mm) |

| Weight | 280KG |